In today’s fast-paced Industry 4.0 environment, effective maintenance is crucial for the success of any operation. As factories involve advanced technologies and assets, maintenance processes are becoming more complicated. Maintenance teams often face asset downtimes, unexpected breakdowns, high repair costs, and disorganized work orders, posing significant business challenges. Without a structured system for asset maintenance, tracking asset maintenance schedules becomes difficult. It’s where the benefits of CMMS come into play, helping businesses streamline workflows, reduce downtime, and improve overall efficiency.

What is a CMMS?

CMMS is a software solution that streamlines asset maintenance operations. It automates the key maintenance processes and helps businesses track assets, schedule maintenance, manage the asset maintenance work orders, and efficiently monitor inventories. CMMS implementation benefits factories as it eliminates the need for manual logs or spreadsheets. The CMMS helps to centralize the asset maintenance data, reduces human errors, and improves the response time. The benefits of CMMS enable the teams to shift from reactive maintenance to proactive strategies like preventive and predictive maintenance, minimizing downtime and repair costs.

Why is CMMS Essential for Maintenance Operations?

Poor asset maintenance management can lead to frequent asset failures, increased downtime, and higher repair costs, impacting profitability and productivity. With Industry 4.0, manufacturing, healthcare, and logistics industries depend on well-maintained assets to ensure operational efficiency, regulatory compliance, and safety. From managing hospital equipment to overseeing factory machinery, CMMS software use cases span various industries, helping businesses minimize downtime and maximize efficiency. A CMMS enables companies to enhance their maintenance processes by streamlining maintenance operations.

With the benefits of CMMS, your organizations can easily:

- Reduces unplanned downtime by scheduling preventive maintenance.

- Extends asset lifespan by tracking equipment performance and repairs.

- Automates work orders to streamline task assignments and completion.

- Enhances compliance by maintaining accurate maintenance records.

- Improves inventory management by tracking spare parts and reducing stockouts.

- Provides data-driven insights to optimize maintenance strategies and costs.

Implementing a CMMS offers significant maintenance management software benefits, from reducing downtime to improving compliance and asset longevity. By streamlining maintenance operations, businesses can enhance efficiency, cut costs, and boost overall productivity.

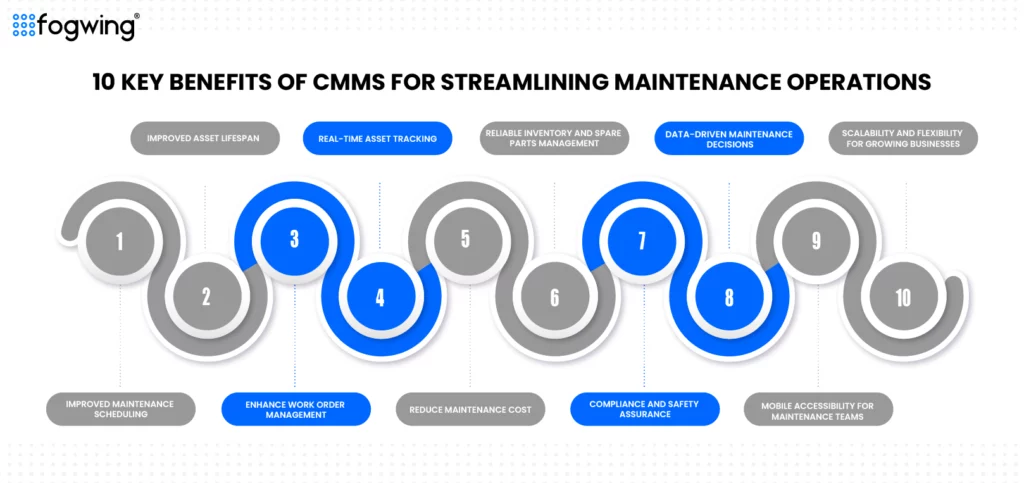

10 Key Benefits of CMMS

A CMMS is a game-changer for businesses looking to streamline maintenance operations. From reducing downtime to improving asset longevity, CMMS automates critical tasks, helping organizations run more efficiently. Here are 10 key benefits of CMMS that can transform your maintenance strategy.

1. Improved Maintenance Scheduling

Unplanned asset breakdowns interrupt factory operations and can lead to costly disruptions. Advanced CMMS software like Fogwing CMMS automates preventive maintenance tasks, ensuring that the asset receives timely servicing, eventually reducing the risk of unexpected failures. One of the key CMMS implementation benefits is its ability to shift maintenance strategies from reactive to proactive, ultimately minimizing downtime and operational disruptions. It helps the maintenance team track the asset’s maintenance history and schedules. It enables businesses to improve asset reliability and make data-driven decisions.

2. Improved asset Lifespan

Frequent asset breakdowns and reactive maintenance shorten the asset lifespan and increase maintenance costs. The Fogwing CMMS enables the business to extend the asset lifespan by enabling proactive maintenance and real-time performance tracking. One of the key benefits of CMMS is its ability to shift businesses from reactive to proactive maintenance, ensuring that equipment is serviced before failures occur. By tracking real-time asset performance, CMMS helps reduce wear and tear, extending machine longevity and improving overall operational efficiency. Various CMMS software use cases, such as manufacturing and logistics, demonstrate how proactive maintenance strategies can significantly cut costs and enhance asset reliability.

3. Enhance Work Order Management

Managing maintenance work orders manually can be chaotic, time-consuming, and error-prone. One of the key benefits of computerized maintenance management system like Fogwing CMMS is its ability to organize maintenance work orders digitally. It helps the maintenance team assign and track work orders efficiently. Businesses can reduce delays, enhance response times, and streamline maintenance workflows by eliminating paperwork bottlenecks. The Benefits of CMMS extend to industries like manufacturing, where companies have significantly reduced maintenance backlogs through automated work orders.

4. Real-Time Asset Tracking

Keeping track of many assets can be confusing and tiring at times. CMMS like Fogwing CMMS provides visibility into asset health and performance, helping teams detect early warning signs before the asset breakdown occurs. The CMMS implementation benefits users by providing access to instant asset health and performance data. Integrating IIoT and sensor technology enables predictive maintenance, minimizes downtime, and ensures optimal asset utilization. Real-time tracking allows the mainteance team to monitor their assets around the clock, eliminating the possibility of human error.

5. Reduce Maintenance Cost

Inefficient maintenance and unexpected breakdown of industry assets lead to high labor costs, frequent repairs, and budget overruns. The key benefits of CMMS is its ability to optimize resource allocation efficiently by ensuring the scheduling of maintenance tasks. It also ensures that the assets are serviced before the failures occur with the help of preventive and predictive maintenance features. Advanced CMMSs like Fogwing CMMS also help maintenance teams keep track of maintenance budgets and provide complete detailed reports of the maintenance budget. It automates the creation of work orders, eventually allowing businesses to cut unnecessary expenses and improve overall cost efficiency significantly.

6. Reliable Inventory and spare Parts Management

Spare parts management is essential in asset maintenance, as running out of parts or overstocking leads to production delays, operational inefficiencies, and increased costs. One of the benefits of a computerized maintenance management system like Fogwing CMMS is the real-time tracking of inventory levels and the provision of automated reorder alerts. It ensures that critical parts are always available when required. CMMS prevents stockouts, reduces emergency purchases, helps businesses save money, optimizes inventory control, and improves maintenance efficiency.

7. Compliance and Safety Assurance

Failure to comply with rules results in legal problems, substantial fines, and safety risks. One key maintenance management software benefits is its ability to streamline compliance by storing asset maintenance reports, safety records, and maintenance logs in a centralized system. The CMMS helps businesses adhere to OSHA, ISO, and other industry regulations, documenting all maintenance activities well. By proactively managing safety checks and asset maintenance, organizations can reduce burdens, enhance workplace safety, and prevent costly accidents.

8. Data-Driven Maintenance Decisions

One of the key benefits of CMMS is its ability to collect and analyze asset maintenance data, enabling managers to make informed, data-driven decisions. By identifying trends and inefficiencies, Fogwing CMMS helps optimize maintenance schedules, reduce downtime, and improve asset performance. Various CMMS software use cases across industries, such as manufacturing and logistics, show how leveraging maintenance analytics can maximize ROI and eliminate inefficient practices.

9. Mobile Accessibility for Maintenance Teams

With the increased popularity of Industry 4.0, manufacturers prefer light-out manufacturing, where industries operate autonomously with minimal human intervention. So, mobile accessibility of maintenance tasks is essential in smart factories for managing their operations. One of the significant benefits of CMMS is its mobile accessibility, allowing maintenance teams to access work orders, receive real-time updates, and report issues from anywhere. It reduces response times for urgent repairs and ensures seamless communication between teams. One key Fogwing CMMS implementation benefits is keeping asset maintenance operations running smoothly, even in remote or large-scale facilities, improving overall efficiency and collaboration.

10. Scalability and Flexibility for Growing Businesses

As companies grow, maintenance operations become more complex, requiring a system that can adapt to increasing assets, multiple locations, and higher workloads. It is where the Fogwing CMMS can help manufacturers. One of the key benefits of CMMS is its ability to scale seamlessly, ensuring that maintenance teams can efficiently manage operations without disruptions. Fogwing CMMS enables seamless scalability by managing increasing assets, multiple locations, and growing workloads. Additionally, CMMS implementation benefits include integration with EAM and APM, allowing businesses to maintain efficiency and streamline processes as they expand.

How to Choose the Right CMMS for Your Business

Choosing the right CMMS is essential to maximizing maintenance management software benefits and ensuring efficient asset management. A user-friendly and intuitive interface simplifies adoption, while customization options help tailor the software to industry-specific needs. Seamless integration with existing ERP, IoT, EAM, and APM further enhances productivity. Businesses must also weigh the benefits of CMMS in cloud-based solutions—offering remote access and scalability—against on-premises options that provide greater data control.

Checklist for Choosing a CMMS

While choosing the right CMMS for your factory asset maintenance, it is essential to consider whether the CMMS application’s user interface is easy to navigate and user-friendly. Consider whether it can be customized to meet your industry-specific needs and ensure the software integrates seamlessly with your existing systems. Additionally, verify if the CMMS offers mobile access for technicians on the go, enabling them to manage asset maintenance activities remotely. By evaluating these criteria, businesses can select the right CMMS to optimize maintenance operations effectively.

Conclusion

Implementing a CMMS software like Fogwing CMMS is essential for businesses aiming to enhance maintenance management operations, reduce costs, and improve asset reliability. The benefits of CMMS include proactive maintenance scheduling, extended asset lifespan, automated work order management, real-time asset tracking, and improved compliance. Additionally, CMMS enhances compliance, provides data-driven insights, offers mobile accessibility, and scales with business growth. With Fogwing CMMS, businesses can leverage CMMS implementation benefits such as predictive maintenance, IoT-enabled asset tracking, and seamless integration with ERP and EAM systems. By adopting Fogwing CMMS, industries can transition from reactive to proactive maintenance, maximize asset utilization, and ensure long-term business growth.

FAQs

1. What is the primary benefit of the maintenance management system?

- Centralized Server: The centralized server allows the team to track real-time asset data and maintenance history more effectively.

- Improved Inventory Management: CMMS tracks and monitors the stock levels of spare parts and automates reorders.

- Reduces Unplanned Downtime: Timely schedules predictive and preventive maintenance to prevent unexpected breakdowns or downtimes.

- Extends Asset Lifespan: Tracks the asset’s maintenance schedules and schedules timely upkeep to increase longevity.

- Automates Work Order Management: The CMMS enables the maintenance team to digitally assign, track, and execute the maintenance work ordered efficiently.

- Provides Real-time Asset Monitoring: CMMS tracks the asset performance with the help of IoT and analytics.

- Reduce the Maintenance Costs: Prevents expensive emergency repairs with proactive strategies.

- Supports Mobile Access: The CMMS software enables the maintenance team to work remotely and manage work orders from anywhere.

2. How does CMMS improve equipment lifespan?

- Scheduled Preventive Maintenance ensures timely servicing to prevent wear and tear.

- CMMS utilizes the IoT and Analytics to detect potential failures before they occur and schedules the predictive maintenance.

- Tracks equipment health and performance to address issues early with real-time asset monitoring.

- Ensures maintenance tasks are assigned and completed on time with automated work order management.

- Maintains optimal operating conditions for machinery with proper lubrication and calibration tracking.

- Centralized data prevents maintenance delays and missed inspections and reduces human errors.

- Ensures timely replacement of worn-out components with optimized spare parts management.

- Helps identify patterns and implement long-term reliability improvements with performance analytics & reporting.

3. Can a CMMS help reduce downtime?

Yes, a CMMS helps reduce downtime by ensuring assets are serviced before failures occur. It automates work order management, streamlining task assignments and reducing delays. Real-time asset monitoring helps detect early warning signs, allowing quick interventions. Additionally, inventory tracking ensures spare parts are available, preventing extended downtime. With data-driven insights, CMMS optimizes maintenance schedules, minimizes disruptions, and improves asset reliability. A system like Fogwing CMMS enhances operational efficiency, reduces repair costs, and keeps equipment running smoothly, maximizing productivity.

4. What industries benefit the most from CMMS?

The sectors that benefit the most from CMMS include:

- Manufacturing – Ensures machinery uptime, schedules preventive maintenance, and reduces production delays.

- Healthcare – Maintains medical equipment compliance, tracks asset usage, and ensures patient safety.

- Facilities Management – Manages building maintenance, HVAC systems, and security equipment efficiently.

- Oil & Gas – Prevents equipment failures, ensures safety compliance, and optimizes asset performance.

- Utilities & Energy – Enhances infrastructure reliability for power plants, water treatment, and renewable energy.

- Logistics & Transportation – Manages fleet maintenance, tracks vehicle health, and minimizes breakdowns.

- Food & Beverage – Ensures regulatory compliance, maintains refrigeration units, and prevents contamination risks.

- Industries with heavy machinery, strict regulations, or high equipment dependency greatly benefit from CMMS solutions like Fogwing CMMS, improving efficiency and cost savings.