In the fourth industrial revolution, asset maintenance and management systems were crucial as most industries depended on machines and equipment for their production operations. A proper maintenance management system will help industries reduce costs, minimize asset downtime, and maximize productivity.

EAM and CMMS are the most used asset maintenance and management platforms. Industries need to understand the difference between EAM and CMMS. This article explores EAM vs CMMS features and offers guidance on selecting the best system for your industry.

Understanding the Basics of EAM vs CMMS

CMMS and EAM allow the maintenance team to simplify maintenance tasks, track assets, and ensure compliance with industry regulations. While both platforms help the maintenance team with maintenance operations, the comparison between the CMMS features and EAM lies in their operational functionality.

A CMMS focuses on asset maintenance management tasks like work order management, preventive maintenance, inventory tracking, and maintenance report creation. EAM manages the complete asset lifecycle, including asset installation, contract management, and disposal.

What is EAM?

Enterprise Asset Management, or EAM, is software used to handle the entire lifecycle of physical assets. From asset procurement to asset disposal, EAM helps the maintenance team optimize asset performance. An EAM covers asset management features like financial planning, risk assessment, and contract tracking.

Key Features and Functionalities of EAM include:

Understanding the key functionality of EAM and CMMS is crucial for selecting the right solution for your business. While both systems support maintenance operations, EAM software goes beyond maintenance to provide complete asset lifecycle management and strategic planning.

- Effective lifecycle management of assets helps the maintenance team track and optimize assets from procurement to decommissioning.

- Work order and maintenance management automates scheduling, assigning, and tracking maintenance activities.

- Inventory and spare parts management efficiently manages the parts inventory and ensures the availability of critical parts, reducing downtime.

- Compliance and risk management help businesses meet industry regulations and minimize operational risks.

- Analytics and reporting provide insights into asset performance, maintenance costs, and efficiency.

- Integration with ERP systems connects EAM software with finance, HR, and supply chain management.

Industries That Benefit the Most from EAM

The difference between EAM and CMMS systems shows that EAM systems are best suited for industries that require long-term asset planning and comprehensive asset management strategies. These industries include:

- Manufacturing – Enhances equipment reliability and reduces unplanned downtime.

- Energy and Utilities – Ensures the smooth operation of organizations like power plants and water treatment facilities.

- Transportation and Logistics – Manages fleets, railway systems, and aviation assets.

- Oil and Gas – Enhances safety, compliance, and efficiency in refineries, pipelines, and drilling operations.

- Public Infrastructure – Assists municipalities in managing roads, bridges, and utilities.

When comparing CMMS features vs EAM features, it’s essential to consider your industry needs. If you require basic maintenance management, CMMS software is a great choice. However, for organizations looking for a complete asset management solution, EAM software provides incredible long-term benefits.

What is CMMS?

Computerized maintenance management system (CMMS) software is designed to streamline asset maintenance operations. It helps the maintenance team automate maintenance work orders, schedule preventive maintenance, prepare maintenance reports, manage parts inventory, and track asset performance.

The difference between EAM and CMMS software lies in its scope; CMMS focuses only on maintenance operations. The EAM offers a broader asset management strategy that includes asset contract management, risk management, and compliance tracking.

Key Features and Functionalities

An effective CMMS software provides businesses with essential maintenance management functionalities, including:

- The maintenance work order management enables the maintenance team to create, assign, track, and execute asset maintenance work orders to ensure timely upkeep.

- The preventive maintenance scheduling feature of the CMMS platform enables the team to automate routine asset maintenance and reduces unplanned asset downtime.

- Fogwing CMMS’s advanced Asset 360 feature enables users to monitor asset performance, maintenance history, inventory management, and financial history.

- Spare parts or inventory management is a crucial part of maintenance management. It ensures the availability of parts for efficient maintenance operations.

- Compliance tracking enables businesses to adhere to industry regulations and safety standards.

- The CMMS software’s user-friendly reporting and analytics feature provides insights into maintenance efficiency, costs, and asset reliability.

When conducting an EAM vs CMMS comparison, it’s clear that CMMS software is ideal for organizations that need a maintenance-focused solution without the complexities of complete asset lifecycle management.

Industries That Benefit the Most from CMMS

The difference between EAM and CMMS systems shows that CMMS systems are widely used in industries with top priorities for maintenance efficiency and equipment reliability. These industries include:

- Manufacturing – Ensures smooth production by reducing machine breakdowns and improving uptime.

- Healthcare – Manages hospital equipment and facility maintenance for optimal patient care.

- Hospitality – Helps hotels and resorts maintain HVAC, plumbing, and electrical systems.

- Facilities Management – Supports the maintenance of buildings, office spaces, and utilities.

- Retail and Warehousing – Keeps storage facilities and logistics operations running smoothly.

Choosing between an EAM and a CMMS for the maintenance system depends on a business’s asset management needs. CMMS software is best for organizations focused solely on maintenance and repairs, while EAM software is better suited for industries requiring comprehensive asset lifecycle management.

Difference Between EAM and CMMS: Key Factors to Consider

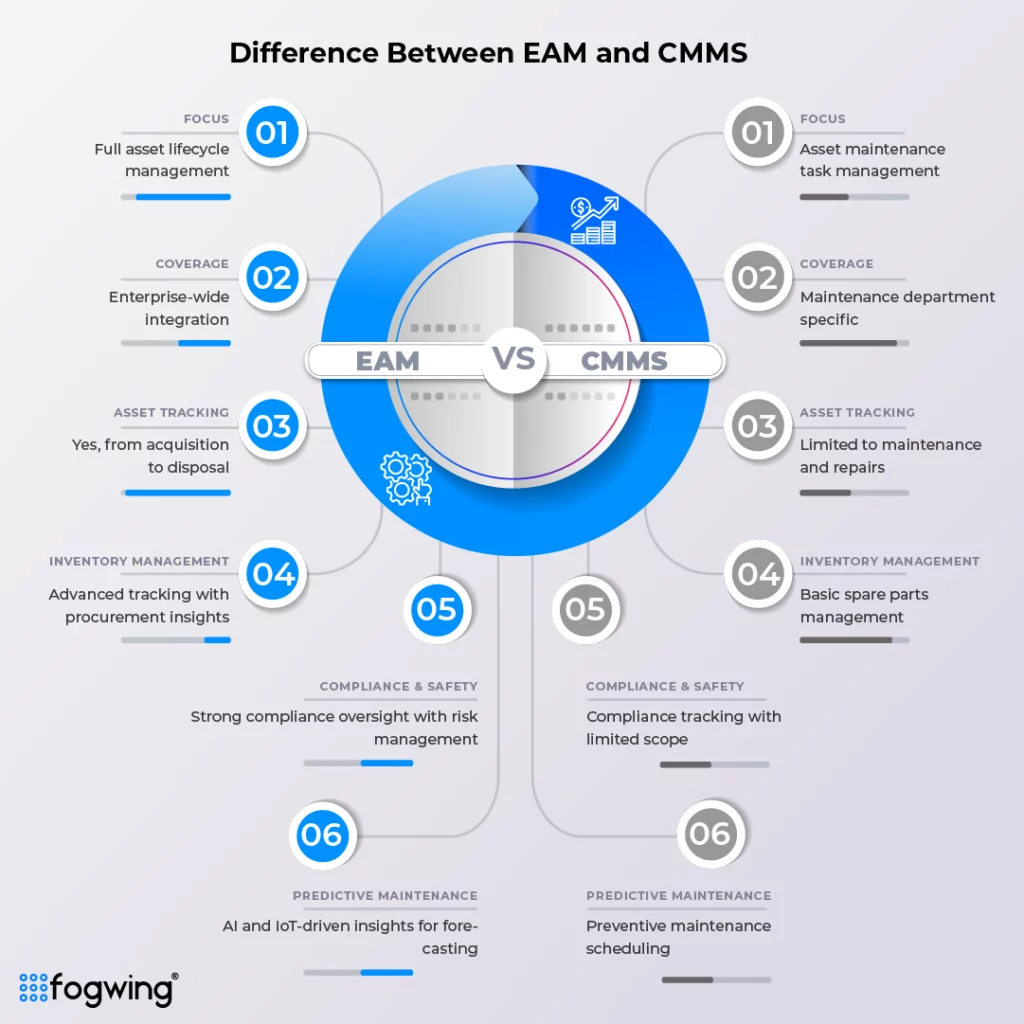

When comparing EAM vs CMMS, it’s essential to understand their core differences, as each system serves unique business needs. While both aim to improve maintenance efficiency and asset reliability, the difference between EAM and CMMS lies in their scope, functionalities, and long-term value. Let’s compare CMMS and EAM features.

| Feature | EAM | CMMS |

| Focus | Full asset lifecycle management | Asset maintenance task management |

| Coverage | Enterprise-wide integration | Maintenance department-specific |

| Asset Tracking | Yes, from acquisition to disposal | Limited to maintenance and repairs |

| Inventory Management | Advanced tracking with procurement insights | Basic spare parts management |

| Compliance & Safety | Strong compliance oversight with risk management | Compliance tracking with limited scope |

| Predictive Maintenance | AI and IoT-driven insights for forecasting | Preventive maintenance scheduling |

This EAM vs CMMS comparison highlights how EAM systems offer a broader, strategic approach to asset management.

In summary, if your business needs to extend beyond maintenance—such as capital planning, procurement, and regulatory compliance—EAM is the more comprehensive choice. However, CMMS software provides an affordable and focused solution for companies looking to manage day-to-day maintenance activities efficiently.

How to Choose the Best Maintenance System for your Business?

- Identify your business size, industry type, and maintenance goals.

- Evaluate both current and future asset maintenance demands.

- Compare CMMS vs EAM and choose based on scope and your requirements.

- Ensure the system can grow with your business and integrate with existing tools (like ERP or IoT systems).

- Look for features like preventive maintenance, work order tracking, mobile access, and real-time analytics.

- Choose a user-friendly interface and strong vendor support or training.

- Test the system in your environment before committing.

Key Questions to ask before selecting a system

1. What are your Asset management requirements?

Evaluate whether you require basic maintenance tracking or a more comprehensive system comprising asset planning, analytics, and compliance

2. Do you require full lifecycle tracking or a maintenance management system?

If you are looking for a maintenance management system, CMMS software is the best choice. An EAM system is more suitable for strategic asset control. Fogwing EAM and CMMS can assist your business with that.

3. What are Your Budget and scalability requirements?

Compare CMMS features vs EAM features, list what is essential for you, and select the platform according to your budget and requirements. CMMS software is generally more cost-effective and easier to implement. EAM, while more complex, offers long-term value and enterprise-wide scalability.

Addressing these key questions will help you confidently select the EAM or CMMS system that best aligns with your operational goals and business growth strategies.

Future Trends: Will EAM and CMMS Converge?

Rapid technological advancements are narrowing the gap between EAM and CMMS. Innovations like IoT, AI, and ML transform how assets are monitored and maintained. They enable real-time asset tracking, predictive maintenance, preventive maintenance, and data-driven decisions—features once exclusive to EAM, now in modern CMMS tools.

Cloud adoption and mobility are also driving this shift. Organizations increasingly opt for cloud-based platforms that provide mobile access, remote monitoring, and real-time collaboration. In response, EAM and CMMS providers are enhancing their offerings to support mobile workflows and facilitate more effortless scalability.

The next wave of evolution will likely bring hybrid systems that combine both strengths, offering comprehensive lifecycle asset management and streamlined maintenance features. This trend is evident in the growing number of platforms that aim to blur the lines between EAM and CMMS functionalities.

A detailed CMMS software comparison today may still show distinct differences, but the gap is closing fast. As businesses prioritize flexibility, integration, and intelligence, future solutions are expected to deliver a unified experience.

Conclusion

Ultimately, selecting the right maintenance system hinges on your business goals, asset complexity, and long-term strategy. CMMS excels at streamlining day-to-day maintenance and enhancing efficiency, while EAM provides a comprehensive framework for managing the entire asset lifecycle, which is vital for strategic planning.

To determine the best fit for your organization, start by thoroughly assessing your current maintenance processes and future growth projections. Understanding these distinctions will empower you to choose the most effective solution for your business

FAQs

1. Is CMMS the same as EAM?

EAM and CMMS are not the same, though they are closely related. CMMS is a subset of EAM. While CMMS is ideal for organizations that only need to manage maintenance tasks, EAM is suited for businesses that require a broader, enterprise-level view of their assets.

2. Can a business use both CMMS and EAM?

Yes, a business can use both CMMS and EAM, especially when starting with maintenance management and later expanding to full asset lifecycle management through integrated or hybrid systems.

3. What industries benefit the most from CMMS?

Industries that benefit the most from CMMS include:

- Manufacturing – Improves equipment uptime and reduces production downtime.

- Healthcare – Manages medical equipment and facility maintenance.

- Hospitality – Maintains HVAC, plumbing, and electrical systems in hotels.

- Facilities Management – Oversees maintenance of buildings and infrastructure.

- Retail and Warehousing – Keeps logistics operations and storage equipment running efficiently.

- Education – Manages campus facilities and utilities.

- Transportation – Maintains vehicle fleets, terminals, and related assets.

These industries rely on CMMS software to streamline maintenance, increase reliability, and meet compliance standards.

4. Who Should use EAM software?

EAM software is ideal for organizations that manage complex, high-value assets across multiple departments or locations. Businesses that should use EAM include:

- Large Manufacturing Companies – To manage the full lifecycle of production assets.

- Energy and Utilities – For long-term infrastructure planning, compliance, and asset reliability.

- Oil and Gas – To ensure safety, regulatory compliance, and efficient asset utilization.

- Transportation and Logistics – For fleet, rail, and aviation asset tracking and maintenance.

- Public Sector and Infrastructure – To manage roads, bridges, water systems, and city assets.

- Facilities with Extensive Capital Equipment – Including universities, airports, and hospitals.

EAM software is ideal for businesses that require comprehensive asset management, financial planning, and regulatory compliance, extending beyond mere maintenance.

5. How long does it take to implement CMMS or EAM?

Implementing a CMMS or EAM system can take anywhere from a few weeks to several months, depending on your organization’s size, operational complexity, and the features of the chosen platform.

Smaller businesses using cloud-based CMMS solutions like Fogwing CMMS may complete implementation in as little as 3 to 6 weeks. However, for larger enterprises or those opting for comprehensive EAM systems, the process can take 3 to 9 months—especially if it involves data migration, system integrations, user training, and custom configurations.