Best EAM Software for Manufacturing

Transform Manufacturing Operations with Intelligent Enterprise Asset Management

Fogwing EAM Software simplifies asset lifecycle management with 360 views, financials, contractual effectiveness, and health conditions for comprehensive asset management.

Over 10,000+ Manufacturing Operators trust Fogwing for Productive Day

What is EAM Software?

EAM software (Enterprise Asset Management Software) is a digital solution that helps industrial organizations manage the entire lifecycle of physical assets. EAM provides features to manage asset information, tracking availability, usage, maintenance, financials, and performances to improve asset reliability, reduce downtime, and extend asset life, ensuring operational efficiency and cost-effective asset management.

Asset Lifecycle

EAM software helps manage the asset lifecycle from procurement to retirement uniformly. It ensures assets usage at peak performance, enhancing productivity and operational reliability over time.

Asset Financials

By optimizing asset availability, EAM software minimizes operational costs, extends asset lifespan, and reduces unplanned downtime, which leads to significant cost savings across operations and capital investments.

Industry Compliances

EAM systems help ensure compliance with industry standards and safety regulations by maintaining accurate records, audit trails, and maintenance histories, reducing the risk of violations, fines, and legal liabilities.

Fogwing EAM Software Features

Optimize manufacturing operations with advanced enterprise asset management software features, enabling real-time asset monitoring, predictive maintenance, and enhanced operational efficiency.”

Asset Lifecycle Management Made Simple, Smart, and Scalable

Fogwing EAM software offers centralized asset lifecycle management, including process automation from asset procurement, contract management, asset availability, and financial performance in single platform.

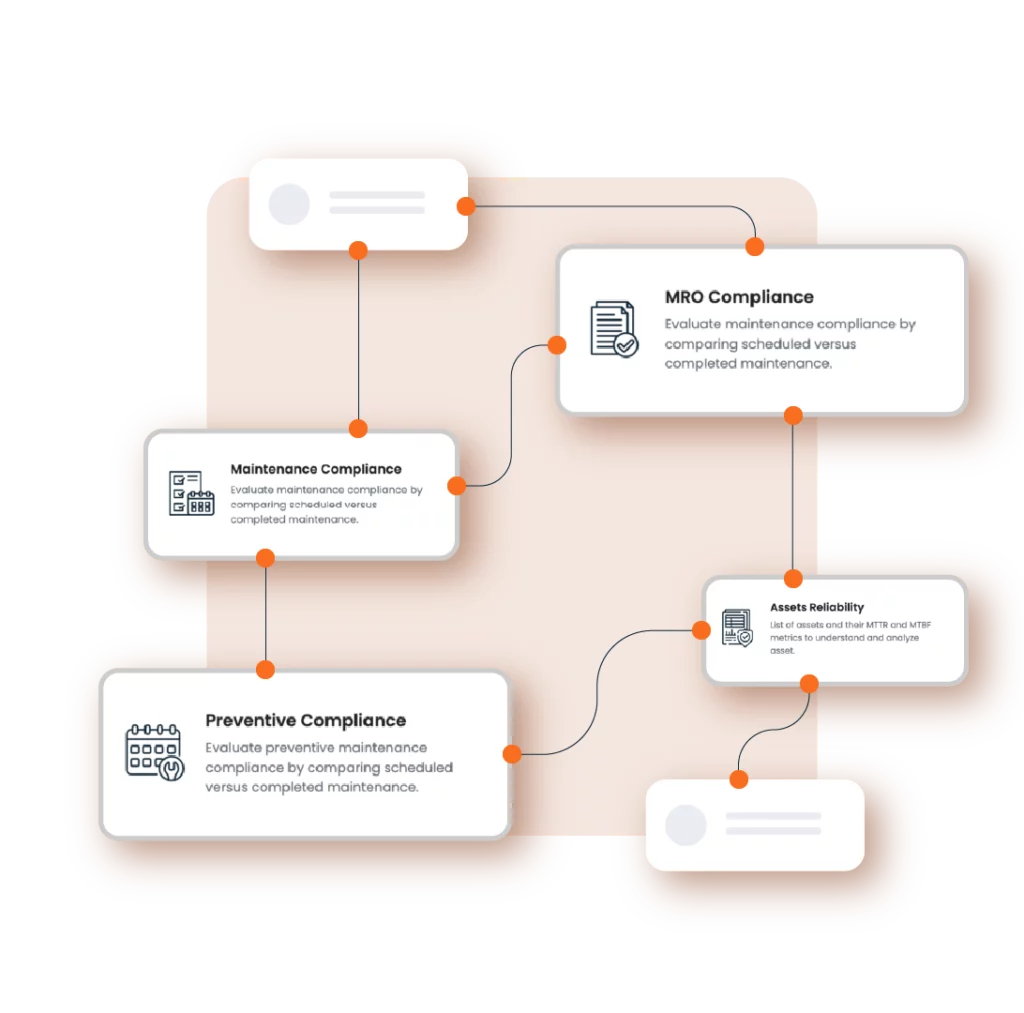

Optimize Maintenance Operations for Industrial Assets

Fogwing helps to streamline industrial asset management and maintenance operations with its comprehensive features. Fogwing EAM enables users to schedule, track, and prioritize maintenance tasks efficiently, optimizing resource allocation and reducing downtime. With real-time insights and analytics, it enhances maintenance effectiveness, prolongs asset lifespan, and improves overall operational efficiency in manufacturing environments.

Govern Asset Hierarchy with Asset Management system

Fogwing enterprise asset management system offers a robust asset hierarchy feature, organizing assets by plant, location, customer, and parent-child relationships. It facilitates granular tracking and management, allowing for detailed analysis and optimization of assets at various levels, ensuring efficient operations and informed decision-making in manufacturing environments.

Elevate Asset Reliability with IoT Enabled Asset Tracking

Fogwing EAM Software, integrated with IoT enhances asset reliability and performance by enabling predictive maintenance. You should Leverage IoT data to identify potential failures before they occur, schedule proactive maintenance, and optimize asset utilization, minimizing downtime and maximizing productivity in manufacturing environments.

Asset Management System to Track Asset Usage and Health

Fogwing Asset Management offers comprehensive asset health monitoring, including real-time usage tracking and health scoring. Utilizing IoT technology delivers actionable insights to optimize asset performance, extend lifespan, and minimize downtime in manufacturing operations.

Manage Assets Financials, and Warranty in One Platform

Monitor asset warranties, service contracts, and licensing agreements to ensure timely renewals and optimize warranty claims and service coverage. Track asset depreciation over time to maintain accurate financial records and comply with accounting standards, enabling better financial planning and budgeting.

Track Asset Locations and Accessibility Limitations

Fogwing Asset Management enables precise asset tracking and real-time monitoring of energy consumption. Leveraging IoT technology, it provides actionable insights to optimize asset utilization and reduce energy costs, enhancing operational efficiency in manufacturing environments.

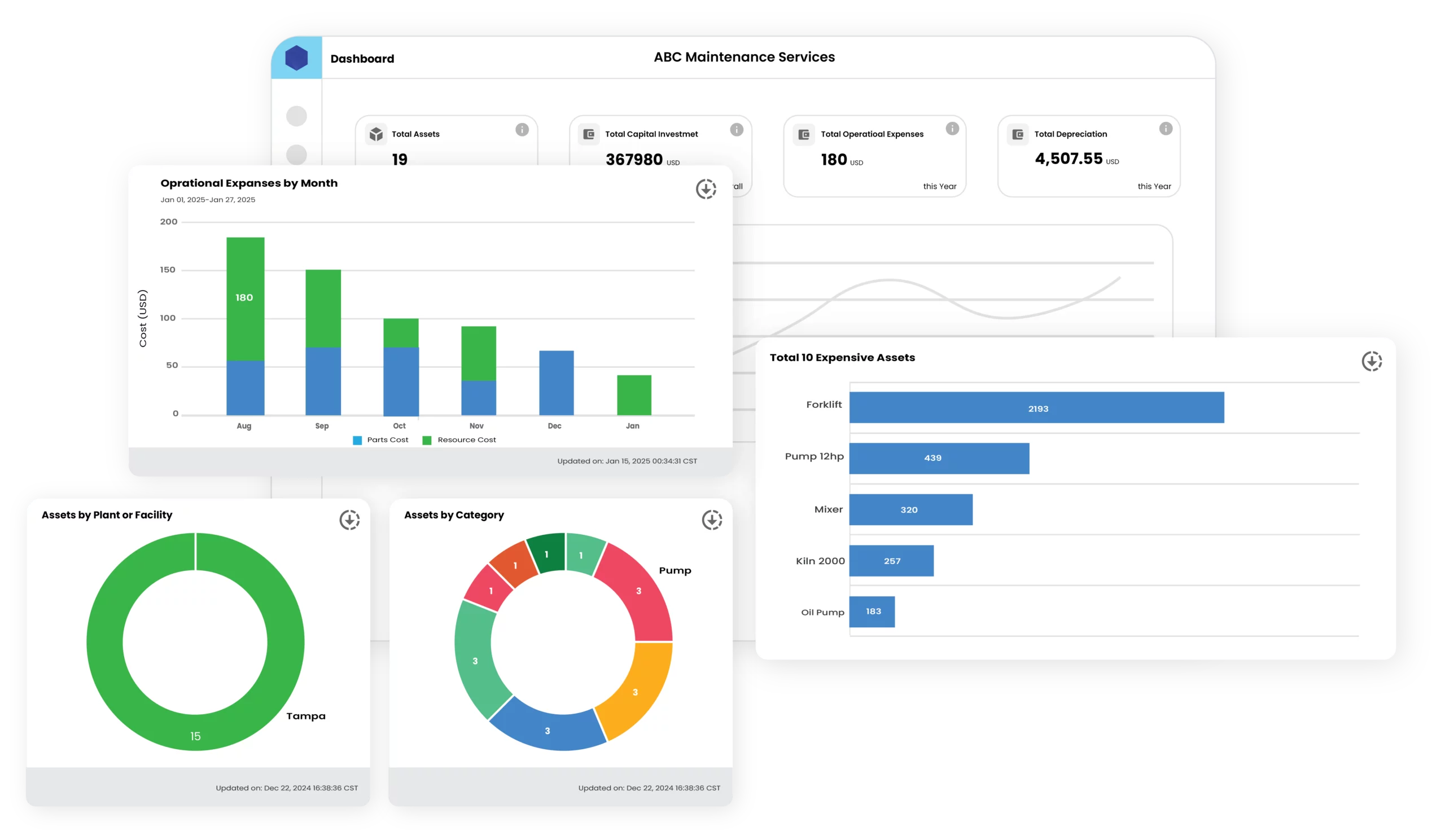

Quick Access Asset Performance Metrics and Reports

Generate comprehensive reports and analytics on asset performance, maintenance history, and lifecycle costs to support data-driven decision-making and continuous improvement initiatives.

Industry Trust Fogwing Smart Manufacturing Platform

Empowering Asset Management for Maximum ROI.

Your asset life and maintenance data are related. Fogwing makes it simple to see 360 views of your asset operations in one place. No more guesswork and less operational cost.

EAM Software FAQs

Common questions that you may have.

EAM (Enterprise Asset Management) focuses on multi-site asset lifecycle management and operational cost optimization. However, CMMS (Computerized Maintenance Management System) is very focused on preventive maintenance, maintenance operations, and maintaining asset availability and performance

Evaluate Business Needs: Identify your business’s specific asset management requirements, including maintenance schedules, asset lifecycle tracking, and real-time monitoring, to ensure the EAM Software aligns with your operational goals.

Scalability and Flexibility: Choose an Enterprise Asset Management (EAM) solution that can adapt to your business growth and handle diverse assets, processes, and multiple locations effectively.

Integration Capabilities: Ensure the EAM software seamlessly integrates with existing ERP, IoT, or CMMS systems to enhance asset management efficiency and data flow across departments.

User-Friendly Interface: Opt for an Enterprise Asset Management (EAM) platform with an intuitive interface and customizable dashboards to simplify operations for all users, from technicians to managers.

Advanced Features and Analytics: Look for EAM software offering AI-powered predictive analytics, real-time condition monitoring, and automation to optimize asset management and maximize ROI.

Enterprise Asset Management (EAM) software streamlines asset management across multi-site operations by providing a centralized platform to monitor and manage assets effectively.

It enables real-time tracking of asset performance, lifecycle stages, and financials, including CapEx, OpEx, and depreciation.

EAM software simplifies asset procurement and contract management, ensuring compliance and cost control.

It optimizes the asset commissioning and decommissioning processes, improving efficiency and reducing downtime.

With its robust tools for lifecycle planning, it supports proactive maintenance and extends asset longevity.

By integrating data from multiple sites, EAM software empowers businesses to make informed decisions, control expenses, and maximize asset value throughout their lifecycle.

ERP (Enterprise Resource Planning) focuses on managing overall business processes like finance, HR, and supply chain, while EAM (Enterprise Asset Management) specializes in maintaining and optimizing physical assets.

ERP offers basic asset tracking, whereas EAM provides advanced tools like lifecycle management, predictive maintenance, and depreciation tracking, ideal for asset-intensive industries.