Learning Center Asset Monitoring Industry 4.0 vs Industry 3.0: A Comparative Journey of Industrial Evolution Industry 4.0 vs Industry 3.0 Industries have undergone transformative phases over the years, each marked

Learning Center

Asset Monitoring

Understanding what SMCP is and its importance

Scheduled Maintenance Critical Percent (SMCP)

In the world of industrial operations, Scheduled Maintenance Critical Percent (SMCP) is a key metric that plays a crucial role in ensuring the efficiency and longevity of machinery and equipment. It helps maintenance teams prioritize work, plan resources, and optimize uptime. This blog explores the concept, its importance, and how to calculate and implement SMCP effectively.

What is SMCP?

Scheduled Maintenance Critical Percent (SMCP) refers to the percentage of critical equipment and systems that are maintained according to a planned schedule. In essence, it measures how much of your critical equipment receives timely, preventive, or scheduled maintenance.

Critical equipment refers to machines or systems essential for the operational processes that, if they fail, could result in significant downtime, safety hazards, or financial losses. By tracking SMCP, organizations can assess whether they are giving adequate attention to these crucial assets.

Importance of SMCP

- Operational Reliability: Regular scheduled maintenance prevents unexpected equipment failures, ensuring operational continuity.

- Cost Management: Preventive maintenance typically costs less than reactive maintenance. Higher SMCP values indicate that the organization is focused on avoiding costly repairs.

- Safety Compliance: Critical equipment failures can lead to safety risks. A high SMCP ensures that essential safety checks and measures are regularly performed.

- Efficiency and Productivity: A well-maintained machine runs more efficiently, increasing productivity and reducing energy consumption.

- Data-Driven Decisions: Tracking SMCP helps maintenance teams analyze trends and make data-driven decisions about maintenance scheduling and prioritization.

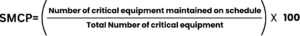

How to Calculate SMCP

SMCP is calculated using a simple formula:

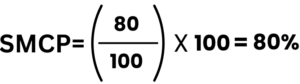

For example, if a facility has 100 critical machines and only 80 of them are serviced as per their scheduled maintenance plan, the SMCP would be:

An ideal target for SMCP is usually between 85% to 100%. Anything lower could indicate lapses in maintenance planning, which can lead to equipment failures and unscheduled downtime.

Factors Affecting SMCP:

- Asset Age: Older assets may have higher SMCP values due to increased wear and tear.

- Maintenance History: A history of frequent failures or breakdowns can also contribute to a higher SMCP.

- Operating Conditions: Harsh operating environments or excessive workloads can increase the risk of failure.

- Maintenance Procedures: The effectiveness of maintenance procedures and the quality of workmanship can influence SMCP.

Best Practices for Improving SMCP

- Prioritize Critical Equipment: Identify and prioritize equipment that is critical to your operations. This helps focus maintenance resources where they are most needed.

- Use Maintenance Management Systems: Implement Computerized Maintenance Management Systems (CMMS) to track and schedule maintenance tasks. CMMS tools automate the scheduling process and ensure no critical equipment is missed.

- Train Your Team: A well-trained maintenance team is essential for timely and effective maintenance. Ensure your staff is equipped with the necessary skills and knowledge to carry out scheduled tasks.

- Monitor and Adjust: Continuously monitor SMCP and make adjustments based on performance data. If the percentage drops, investigate the reasons and take corrective action immediately.

- Optimize Preventive Maintenance Plans: Review maintenance plans periodically to ensure they are aligned with the actual performance and condition of the equipment. Over-maintenance can be as costly as under-maintenance.

Conclusion

Scheduled Maintenance Critical Percent (SMCP) is a critical metric that organizations should use to evaluate the effectiveness of their maintenance programs. It ensures that essential equipment is being maintained on time, reducing the likelihood of failure, improving safety, and lowering operational costs. By focusing on critical equipment, utilizing technology, and constantly monitoring performance, organizations can improve their SMCP, ensuring their operations run smoothly and efficiently.

Get our newsletters delivered directly to your inbox.

By submitting ,you agree to Fogwing Terms of Service. Your personal data will be processed in accordance with Fogwing Privacy Policy.

Read more articles...

Learning Center Asset Monitoring Asset Tracking in Maintenance: Revolutionizing Operational Efficiency Asset Tracking in Maintenance In the world of modern maintenance, asset tracking has emerged as a vital strategy for

Learning Center Asset Monitoring HVAC Preventive Maintenance: Ensuring Optimal Performance and Longevity HVAC Preventive Maintenance HVAC systems are the unsung heroes of our homes and offices, providing comfort and clean