In this blog, we will be learning about purpose of Root Cause Analysis (RCA) and how to leverage for manufacturing operations to reduce the wastes. What is the Root Cause

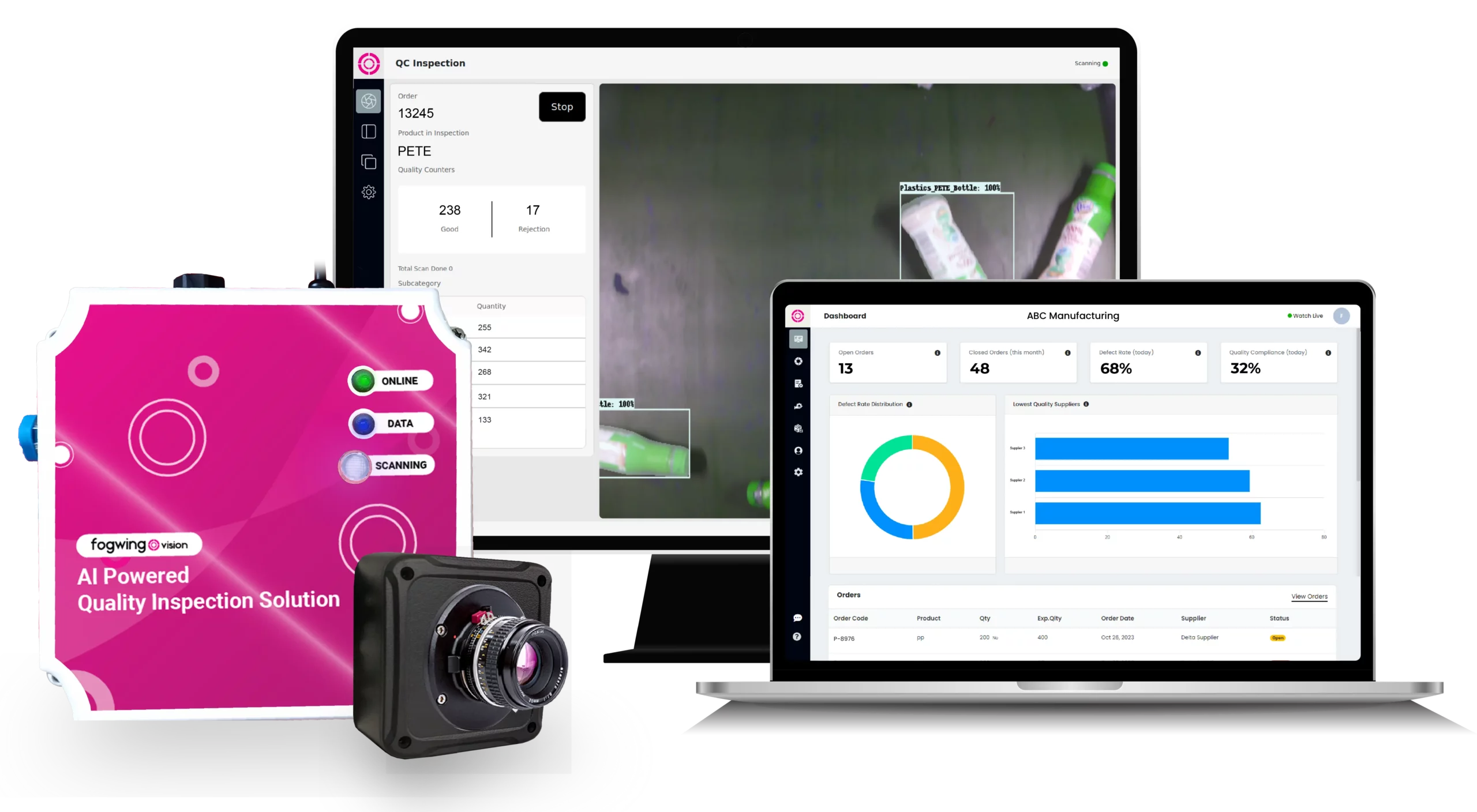

Multiply Quality Check (QC) accuracy with a fully automated Visual Quality Inspection Solution at rapid speed to meet delivery deadlines.

New way of conducting Quality Inspection for higher accuracy and visibility

Fogwing Vision is AI-Powered Quality Inspection Software that enforces intelligent visual inspection through camera equipment to detect the quality issues of supplier materials accurately, half-finished parts, and final products before delivery. Enhance your productivity and quality compliance.

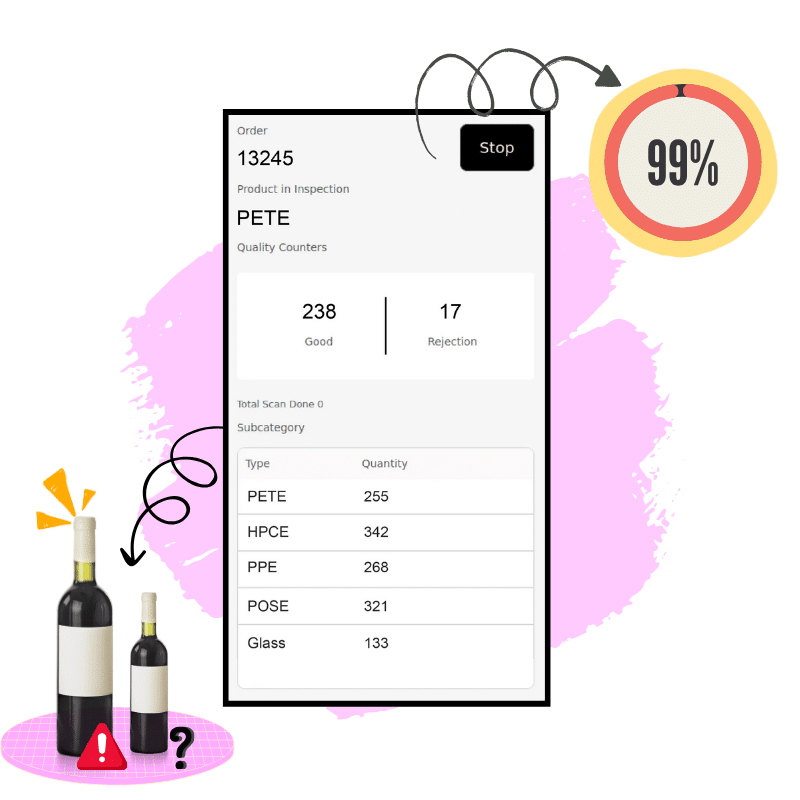

Are you ready to revolutionize your quality checks and elevate your standards by an astounding 99%? Fogwing Vision is here to empower your business with cutting-edge solutions that redefine the way you ensure quality. It is time to adopt newer technologies to identify the deeper defect rating.

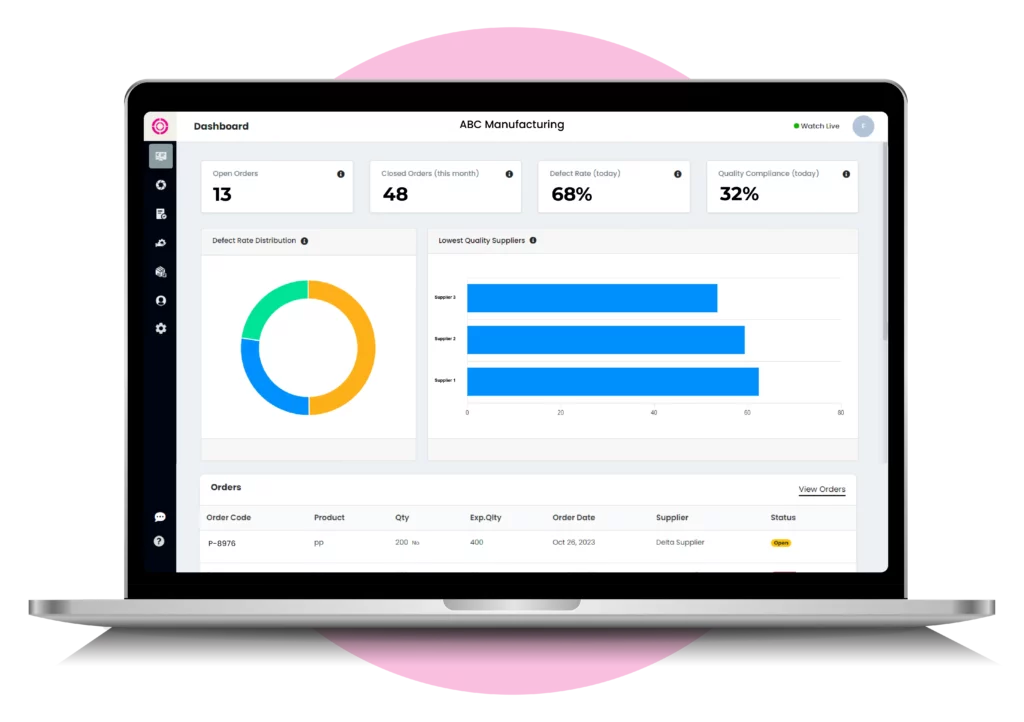

Fogwing Vision solution offers seamless remote access to your quality inspection data, empowering your team with real-time insights from anywhere in the world. Experience the convenience of monitoring and analyzing quality metrics at your fingertips, ensuring that critical decisions are made promptly. With this remote access capability, collaboration becomes more agile, and your operations gains the flexibility to adapt to evolving quality standards.

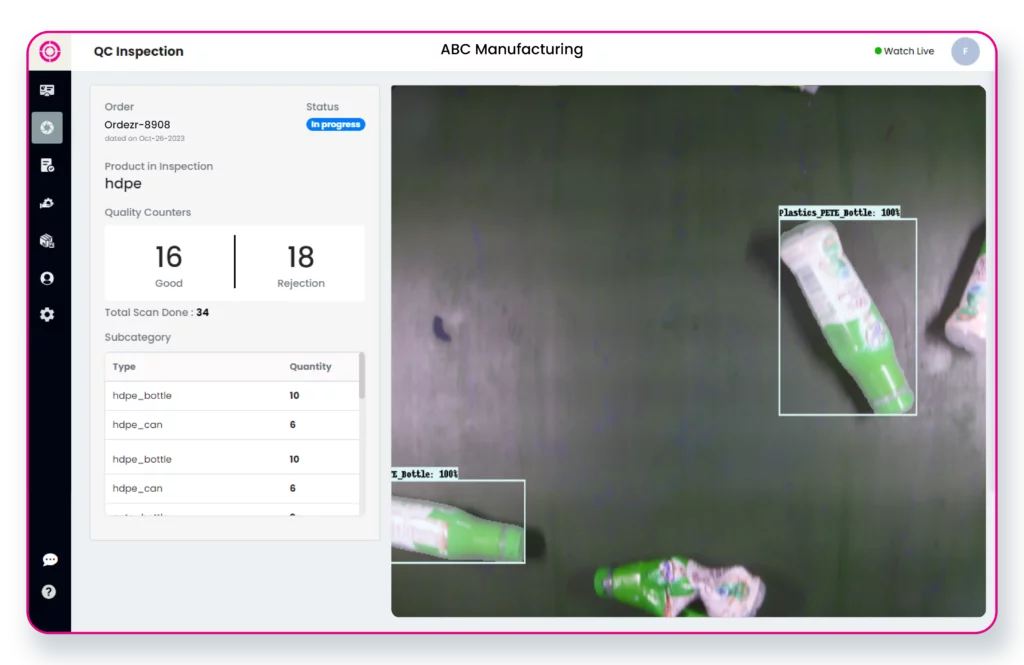

This intuitive dashboard consolidates comprehensive quality inspection metrics into a single, easy-to-navigate interface, offering real-time insights into your plant’s performance. Monitor key quality indicators, track trends, and identify defect trends. The plant-level visibility in quality provided by our dashboard empowers decision-makers to make informed choices promptly, fostering a proactive approach to quality management.

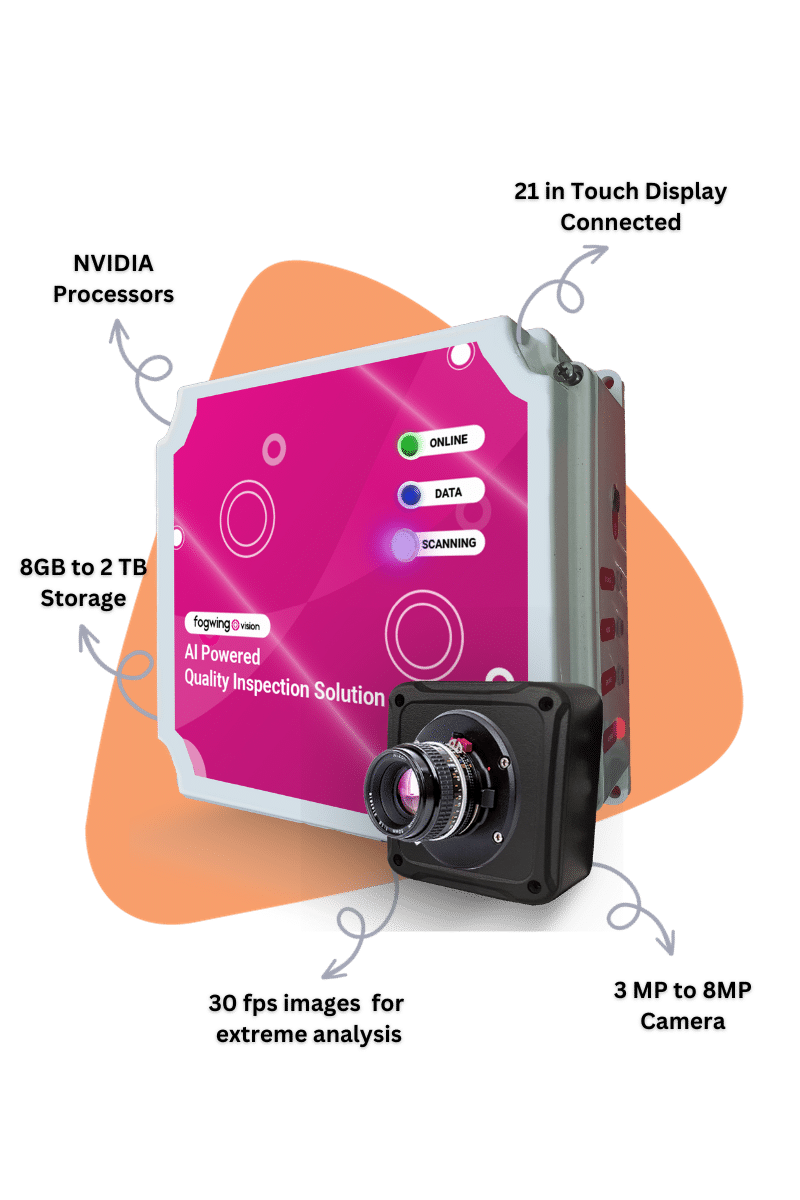

Fogwing Vision devices are equipped with an industrial camera capable of taking 30 fps images and an AI processor with 40 TOPS GPU performance. This can be mounted on the conveyor belts for scanning high-speed production.

For higher accuracy and perfection, every devices loaded with custom ML model trained according to customer requirements.

Fogwing vision devices come with Ubuntu OS, Vision Device Application, Cloud Connector and LED Touch Display for Operators inputs.

Fogwing Edge devices are capable of communicate to Fogwing Cloud directly through WIRED and WIFI network but preferred WIRED.

Visual quality inspection is a process in which products or materials are examined and assessed using visual means to ensure they meet specified quality standards

Fogwing vision devices have a camera and powerful machine learning model that captures 30fps photos of objects and analyzes and identifies the defects within a few seconds.

Fogwing vision implementation takes 8 weeks to 16 weeks, depending on the defect detection and model training complexity.

Fogwing Vision software is available on a subscription basis. But, vision hardware, ML model training, and installation are charged as a one-time fee.

Customer Success

Saahas Zero Waste Management is the provider of end-to-end waste management services based on circular economy principles. While suppliers supply waste materials, it is challenging to segregate the waste materials according to the recycling category. Fogwing Vision…

In this blog, we will be learning about purpose of Root Cause Analysis (RCA) and how to leverage for manufacturing operations to reduce the wastes. What is the Root Cause

In today’s fast-paced Industry 4.0 environment, effective maintenance is crucial for the success of any operation. As factories involve advanced technologies and assets, maintenance processes are becoming more complicated. Maintenance

If you’re working in the manufacturing industry, you’ve probably heard the term ‘Total Productive Maintenance‘ thrown around a lot. But what exactly is it, and how can it benefit your

In 2025, preventive maintenance software plays a crucial role in ensuring seamless operations and extending the lifecycle of industrial assets. With the market flooded with multiple solutions, it’s important to...