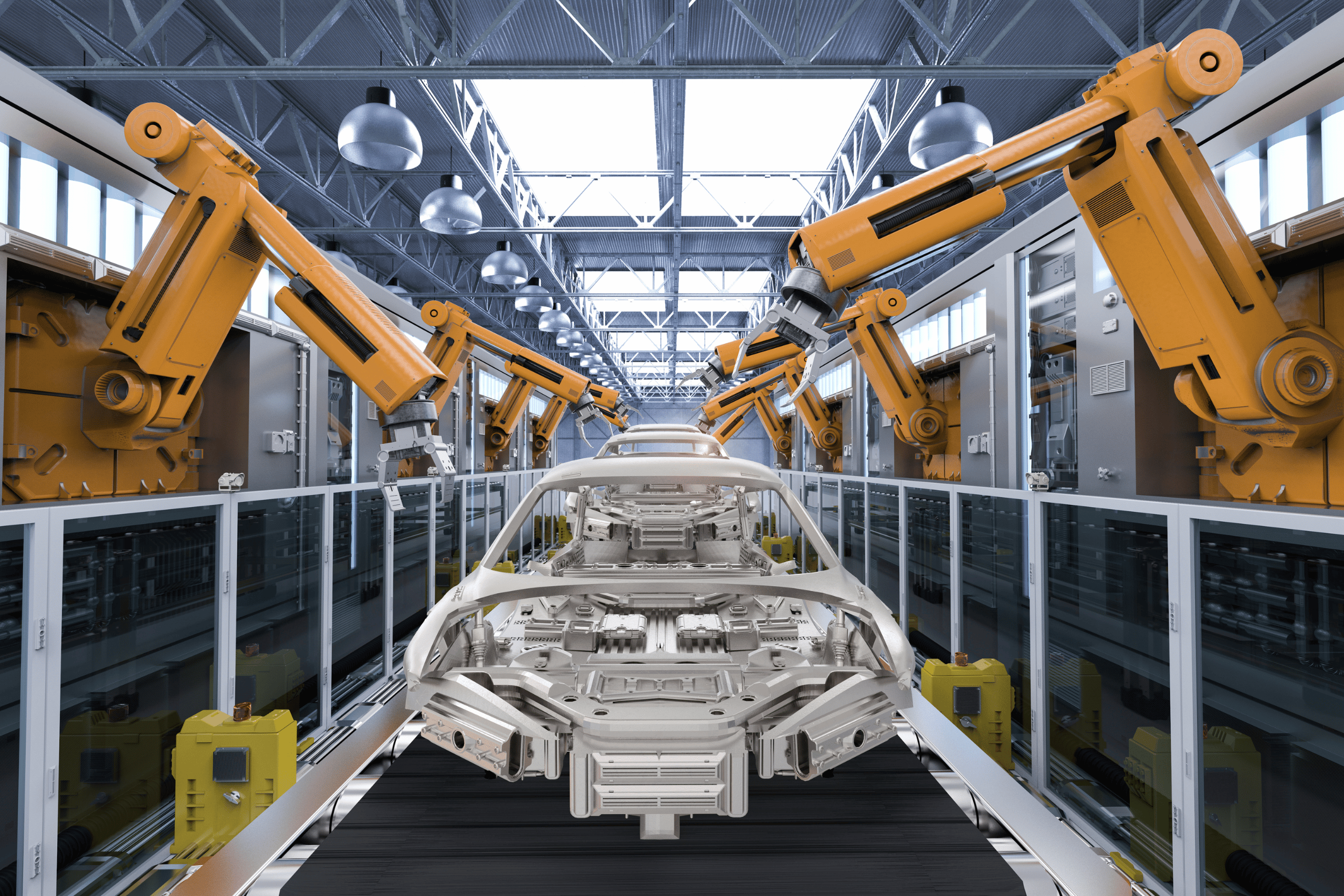

Smart Production Monitoring System for Manufacturing

Fogwing Matrix Software provides all features required to monitor your manufacturing operations from anywhere and anytime. The inbuilt AI-based Manufacturing Intelligence module provides Performance KPIs, Downtime Alerts, Loss based Metrics, Scrap Trends, MTTR and MTBF etc.