What is CMMS - the ultimate guide

Everything you need to know about CMMS or Computerized Maintenance Management System.

In today’s fast-paced industrial landscape, maintaining the health and functionality of equipment is crucial to ensuring operational efficiency and minimizing downtime.

Enter the CMMS – Computerized Maintenance Management System – a game-changing tool designed to streamline maintenance operations and empower businesses to maximize asset performance.

But what exactly is CMMS, and why has it become an indispensable component for modern enterprises?

Let’s dive in.

Table of Contents

What is CMMS?

The CMMS means Computerized Maintenance Management System. CMMS is software that helps organizations streamline maintenance tasks by managing work orders, scheduling preventive maintenance, tracking asset performance, and optimizing inventory.

It improves operational efficiency, reduces downtime, and ensures assets remain reliable and compliant with regulations.

History of CMMS

The history of CMMS dates back to the 1960s and 1970s, when organizations began using basic computerized systems to manage maintenance tasks.

Early systems were often custom-built and ran on mainframe computers, focusing on simple record-keeping and scheduling.

By the 1980s, the rise of personal computers made CMMS more accessible, enabling more sophisticated features like inventory tracking and work order management.

The 1990s saw further advancements with graphical interfaces and integration capabilities.

With the advent of cloud computing and mobile technology in the 2000s, CMMS evolved into flexible, scalable solutions, empowering businesses to streamline maintenance operations and enhance asset performance.

What features does CMMS have?

CMMS should have the following basic features to serve the purpose.

Work Order Management

A CMMS simplifies creating, assigning, and managing work orders.

Maintenance managers can quickly generate work orders with detailed descriptions, assign them to specific technicians, and track their progress in real-time.

This ensures that tasks are completed on time and according to priority.

Additionally, historical data from completed work orders can be used to analyze recurring issues and improve future maintenance strategies.

Preventive Maintenance Scheduling

One of the most critical functions of a CMMS is its ability to automate preventive maintenance tasks.

The system uses predefined schedules based on time, usage, or condition to ensure that equipment is serviced before failures occur.

This proactive approach reduces unplanned downtime and extends the lifespan of assets.

Notifications and alerts help teams stay on top of upcoming tasks, preventing delays.

Asset Management

CMMS serves as a centralized repository for all asset-related information. This includes equipment specifications, purchase dates, maintenance history, warranties, and performance data.

With this information readily available, teams can make informed decisions about repairs, replacements, and upgrades.

The system also helps track asset performance trends, enabling organizations to optimize utilization and plan capital expenditures effectively.

Inventory Management

Managing spare parts and consumables can be challenging without a structured approach.

A CMMS tracks real-time inventory levels, ensuring critical parts are always available. The system can issue alerts when stock levels fall below predefined thresholds, helping organizations avoid delays due to missing parts.

It also tracks usage patterns, allowing for better forecasting and inventory optimization.

Reporting and Analytics

Modern CMMS platforms come equipped with powerful reporting and analytics tools. These tools provide detailed insights into various aspects of maintenance operations, such as equipment downtime, technician productivity, and cost analysis.

Customizable dashboards allow managers to monitor key performance indicators (KPIs) and identify areas for improvement.

Over time, these insights can drive more effective maintenance strategies and cost savings.

Mobile Access

With the rise of mobile technology, many CMMS solutions offer mobile applications. These apps enable technicians to access work orders, update task statuses, and log maintenance activities directly from the field.

Mobile access reduces the need for manual paperwork, enhances communication, and ensures that critical information is always available.

This feature is particularly valuable for organizations with geographically dispersed operations.

What are the benefits of a CMMS?

CMMS offers significant business and operational value across various industries.

By centralizing asset information, automating maintenance processes, and providing actionable insights, CMMS enables businesses to shift from reactive to proactive maintenance approaches

1. Enhanced Asset Management

A CMMS provides a centralized database for all asset-related information, including:

Asset specifications

Maintenance history

Warranty details

This comprehensive data enables maintenance teams to track asset performance, schedule preventive maintenance, and prolong equipment lifespan. With detailed records, identifying recurring issues becomes simpler, facilitating proactive solutions.

2. Improved Preventive Maintenance

Reactive maintenance can lead to unexpected downtime and higher repair costs. CMMS software enables organizations to shift from reactive to preventive maintenance by:

Automating maintenance schedules

Sending alerts for upcoming tasks

Monitoring asset conditions in real-time

Businesses can reduce downtime and maintain consistent operations by addressing potential issues before they escalate.

Explore 10 rules of preventive maintenance for better understanding.

3. Increased Operational Efficiency

Managing maintenance manually often leads to inefficiencies and missed opportunities for optimization. CMMS improves operational efficiency by:

Automating task assignments

Providing a digital work order system

Reducing paperwork and manual errors

Maintenance personnel can instantly access job details, required tools, and parts, minimizing delays and improving productivity.

4. Cost Savings

By optimizing maintenance schedules and extending asset life, CMMS helps reduce maintenance costs. Key cost-saving benefits include:

Minimizing unplanned downtime

Reducing overtime and emergency repairs

Optimizing spare parts inventory

These savings contribute to a better return on investment (ROI) and improved budget management.

5. Compliance and Reporting

Industries such as healthcare, food processing, and energy have strict regulatory requirements. CMMS ensures compliance by:

Maintaining detailed records of maintenance activities

Generating reports for audits

Providing documentation for regulatory inspections

This level of transparency ensures compliance and builds trust with stakeholders.

6. Improved Safety and Risk Management

Equipment failures can lead to hazardous situations for employees and the environment. CMMS reduces risks by:

Enforcing timely maintenance

Tracking safety protocols

Recording safety inspections

A well-maintained asset is less likely to cause accidents, ensuring a safer workplace for all.

7. Data-Driven Decisions

CMMS software provides powerful analytics and reporting tools that allow organizations to make informed decisions. Insights include:

Asset performance trends

Maintenance costs

Resource utilization

With access to accurate data, organizations can prioritize critical tasks, allocate resources efficiently, and plan for future investments.

8. Scalability and Integration

Modern CMMS solutions are designed to grow your business. They can integrate with other systems like Enterprise Resource Planning (ERP) and Internet of Things (IoT) platforms, enabling seamless data flow across departments. This scalability ensures that the CMMS remains a valuable tool as your organization evolves.

9. Environmental Sustainability

CMMS can contribute to sustainability initiatives by:

Optimizing energy usage

Reducing waste through efficient resource management

Monitoring and improving equipment efficiency

Organizations can reduce their carbon footprint and promote sustainability by aligning maintenance practices with environmental goals.

What Industries Use a CMMS?

CMMS is widely adopted across various industries. However, it is more useful to asset-intensive industries such as manufacturing, healthcare, food processing, energy management, oil and gas, mining, and larger facilities.

Manufacturing: CMMS helps ensure production lines run smoothly in manufacturing plants by scheduling routine maintenance and preventing unplanned downtime. For example, an automotive assembly line can use CMMS to monitor the health of robotics and conveyors, ensuring optimal performance.

Healthcare: Hospitals and clinics rely on Healthcare CMMS to manage critical medical equipment such as MRI machines and ventilators.

For instance, a hospital can schedule routine calibrations and repairs for diagnostic tools, ensuring patient safety and compliance with healthcare regulations.

Energy and Utilities: Utility providers leverage CMMS to maintain infrastructure such as power grids, pipelines, and substations.

For example, an electricity provider can use CMMS to track inspections and preventive maintenance for transformers, reducing the risk of outages.

Facilities Management: In commercial and residential properties, CMMS streamlines the maintenance of HVAC systems, elevators, and lighting.

For instance, a large shopping mall can use CMMS to schedule regular inspections and repairs, ensuring a comfortable environment for visitors.

Food and Beverage Industry: Food processing plants use CMMS to maintain compliance with strict hygiene and safety standards.

For example, a dairy facility can track cleaning and maintenance schedules for pasteurizers and packaging machines, reducing contamination risks.

Transportation and Logistics: Fleet management benefits from CMMS by tracking vehicle maintenance schedules and ensuring compliance with safety regulations.

For example, a logistics company can use CMMS to monitor oil changes and tire replacements for its fleet of delivery trucks.

What are the types of CMMS Software?

When selecting a CMMS, understanding the available types is essential to match your organization’s maintenance needs. Here are the main types of CMMS software:

1. On-Premises CMMS

On-premises CMMS is installed and operated on a company’s local servers and infrastructure. This type provides complete control over data and system security, making it suitable for organizations with stringent data protection requirements.

However, it often involves higher upfront costs and ongoing IT support for maintenance.

2. Cloud-Based CMMS

Cloud-based CMMS, also known as Software as a Service (SaaS), is hosted on the vendor’s servers and accessed via the Internet. It is cost-effective, easy to deploy, and scalable, making it ideal for small to medium-sized businesses.

Cloud CMMS eliminates the need for extensive IT infrastructure and offers automatic updates.

3. Mobile CMMS

Mobile CMMS is designed for accessibility on smartphones and tablets, allowing technicians to update work orders, log maintenance tasks, and access asset data from the field.

This type is invaluable for industries with remote or geographically dispersed operations.

4. Open-Source CMMS

Open-source CMMS offers flexibility and customization as organizations can access and modify the source code.

This option suits businesses with technical expertise and specific customization needs but may require significant IT resources.

What is the best CMMS Software?

Finding the best CMMS software for your organization can significantly enhance maintenance efficiency, reduce downtime, and improve asset reliability.

With over 100 options available, each offering unique features like work order management, preventive maintenance scheduling, and real-time analytics, choosing the right one can be overwhelming.

The CMMS market has tools designed to meet diverse business needs, from cloud-based solutions to industry-specific platforms.

To help you make an informed decision, we’ve compiled a detailed comparison of the top 7 CMMS software.

What is the CMMS Software cost?

The CMMS software cost varies widely based on factors such as deployment type, features, and the size of your organization.

Knowing the pricing structure enables informed choices that fit your budget.

Here’s an overview of what to expect.

1. Subscription-Based Pricing

Most cloud CMMS software follows a subscription pricing model. The subscription cost typically ranges from $15 to $200 per user per month. The subscription pricing depends on the number of users, features included (e.g., mobile access or advanced analytics), and support levels.

Explore Fogwing CMMS pricing and features comparison for better understanding.

2. On-Premises Licensing

On-premises CMMS requires a one-time license fee, ranging from $10,000 to $100,000, depending on the system’s complexity.

Additional costs include hardware setup, customization, and ongoing maintenance.

3. Add-On Features

Some of the CMMS vendors provide advanced features like predictive maintenance, IoT integration, or AI-powered analytics, which often come at an additional cost.

These add-ons range from $5 to $50 monthly on subscription basis or require a one-time setup fee.

4. Implementation and Training

Typically, CMMS vendors offer initial implementation, including system setup, data migration, and training, typically ranging from $2,000 to $20,000 cost.

These costs depend on the system’s complexity and the level of customization required.

However, Fogwing CMMS is offered at no additional cost to customers, including the initial setup and data migration. Here is our customer onboarding process and support guidelines.

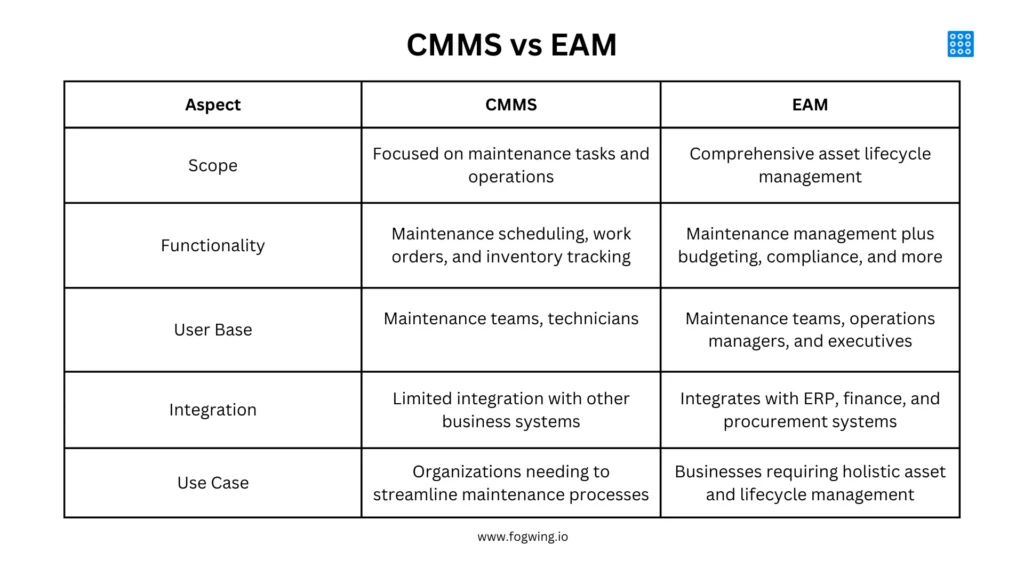

EAM vs. CMMS: the Key Differences

Two terms often arise when managing assets and maintenance operations: EAM (Enterprise Asset Management) and CMMS (Computerized Maintenance Management System).

While both systems aim to optimize asset performance and maintenance efficiency, they serve different purposes and cater to varying organizational needs.

Role of CMMS in Maintennace

CMMS centralizes maintenance data, providing tools to manage work orders, schedule preventive maintenance, track inventory, and generate reports.

Key Features of CMMS:

Work order management

Preventive maintenance scheduling

Asset and equipment tracking

Inventory management for spare parts

Reporting and analytics

CMMS is particularly valuable for organizations looking to improve maintenance efficiency, reduce downtime, and extend the lifespan of critical assets.

What is EAM?

EAM, or Enterprise Asset Management, is a more comprehensive system that goes beyond maintenance to manage the entire asset lifecycle—from acquisition and deployment to maintenance and disposal.

EAM integrates maintenance management with broader business processes, providing a holistic view of asset performance, costs, and long-term planning.

Key Features of EAM:

Asset lifecycle management

Maintenance management (similar to CMMS)

Capital planning and budgeting

Compliance and risk management

Integration with ERP systems

EAM is ideal for organizations with complex operations, multiple facilities, and a need for strategic asset planning.

Can CMMS and EAM Work Together?

In some cases, CMMS and EAM can complement each other. For example, a business might use a CMMS for day-to-day maintenance management and an EAM system for broader asset lifecycle management.

However, many modern EAM systems include robust maintenance management features, reducing the need for separate CMMS software.

CMMS FAQs

The CMMS’s full form is a computerized maintenance management system. CMMS software is used to streamline maintenance operations with digital access to the operational data.

CMMS programs refer to software applications designed to help organizations plan, manage, and optimize maintenance operations.

These programs centralize maintenance-related data and automate tasks to improve efficiency, reduce downtime, and extend asset life.

Key Functions of CMMS Programs:

- Work Order Management: Create, assign, and track maintenance tasks.

- Preventive Maintenance: Schedule maintenance based on time, usage, or condition.

- Asset Tracking: Store and monitor details like equipment history and performance.

- Inventory Management: Track spare parts and manage stock levels.

- Reporting and Analytics: Generate insights on maintenance costs, asset performance, and team productivity.

- Mobile Access: Allow technicians to update work orders and access data on the go.

CMMS programs are widely used across manufacturing, healthcare, energy, and transportation industries to enhance maintenance efficiency and ensure asset reliability.

A CMMS portal is a centralized online platform or interface that provides users access to a Computerized Maintenance Management System (CMMS).

It serves as a gateway for maintenance teams, managers, and other stakeholders to interact with the system, enabling efficient management of maintenance tasks and asset information.

CMMS is used by various roles within an organization to improve maintenance operations, enhance asset reliability, and streamline workflows. Below are the primary users of CMMS and how they benefit from it:

- Maintenance Manager

- Maintenance Engineer

- Asset Manager

- Operational Manager

- Inventory Manager

- IT Manager